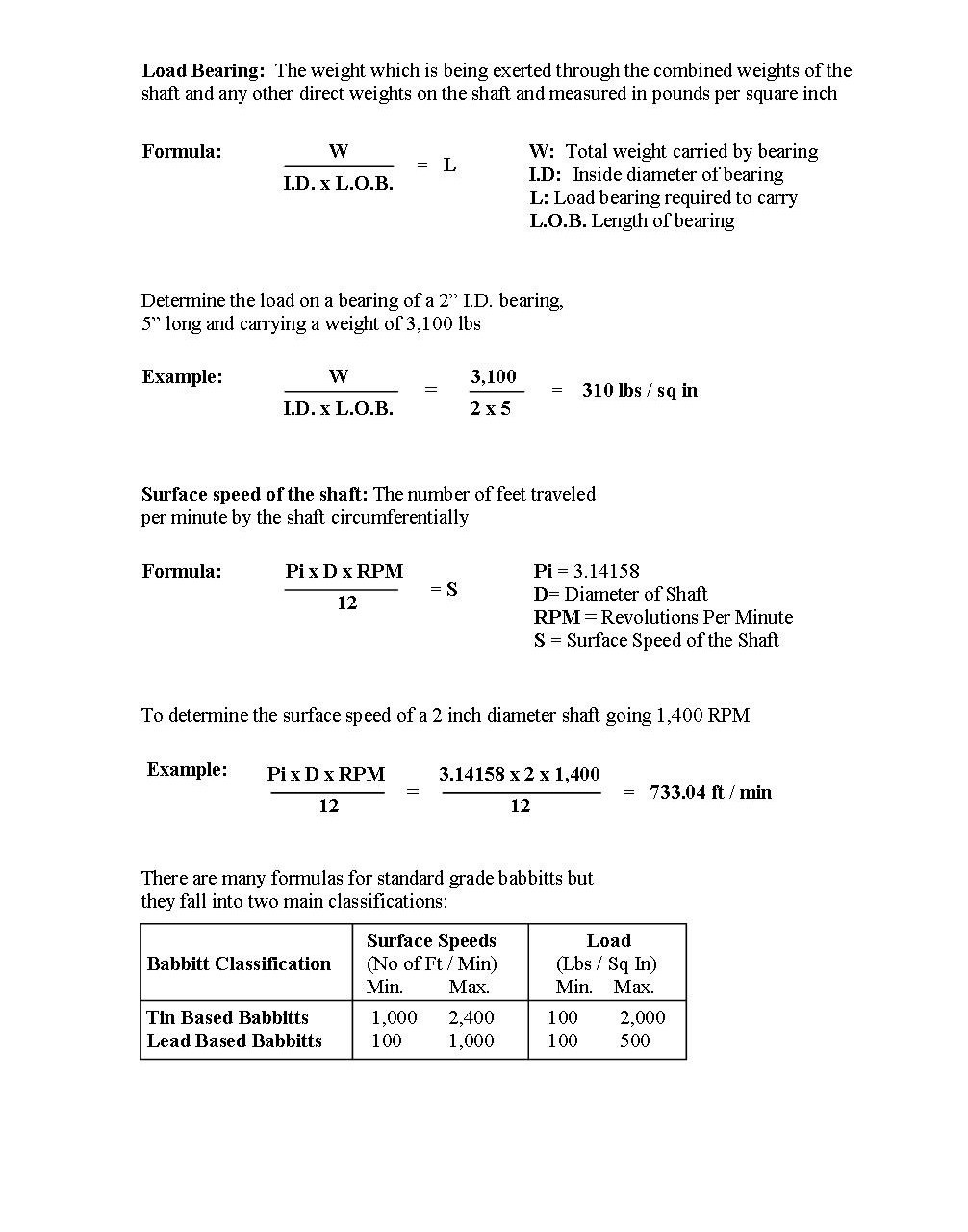

|

Babbitt |

Lbs / Cubic inch |

Melting Temp (F) |

Pouring Temp (F) |

| PREMIER NICKEL: |

.264 |

466-669 |

795-850 |

| May be used for all bearing surfaces requiring a hard white metal where conditions are moderately severe and speeds are high. Applications include electric motors, engines, high speed saws, etc. Lead-free. May substitute for any lead based Babbitt. Meets: ASTM B-23, Grade 2 | |||

| PREMIER DIESEL: |

.267 |

464-792 |

900-1100 |

| Extremely tough and durable lead-free alloy. Used in moderately heavy pressures or reciprocating motion. Applications include diesel engine bearings, rock crushers, and other machinery with heavy pounding. Meets: ASTM B-23, Grade 3 | |||

| NATIONAL ANTI-FRICTION: |

.369 |

464-514 |

625-725 |

| General purpose lead based Babbitt. Excellent alloy where Babbitt speeds are low to medium (600 RPM max) with uniformly heavy loads. Adheres well to steel or bronze. Meets: ASTM B-23, Grade 7, with the exception of no added Arsenic | |||

| PLANER KNIFE: |

.376 |

462-493 |

600-725 |

| Engineered for chipper knife backing. Applications include various light duty work loads. Contains lead. | |||

| AA PACKING: |

.381 |

462-475 |

615-725 |

| Designed as a cost saver to Planer Knife Babbitt. Low melting temperature and easy pouring make this leaded alloy a good all around babbitt. | |||

| N-F NO. 4: |

.387 |

477-490 |

625-725 |

| Economy priced leaded alloy designed especially for light loads and slow speed applications. Primarily used as a backing or filler material. Exceptionally low shrinkage alloy. | |||

| N-F COPPER HARD: |

.329 |

430-590 |

700-800 |

| General purpose leaded babbitt for machine shop requirements. Works well with thin bearings of light running machinery with light to medium pressures such as compressors, electric motors, pumps and stationary engine parts. | |||

| PREMIER STERNBEARING: |

.380 |

462-475 |

600-725 |

| High quality lead based babbitt has excellent corrosion properties. Used in shipboard applications. | |||

| Babbitts are manufactured to ASTM-B23, SAE J460, AMS, Military and Customer Specifications. | |||